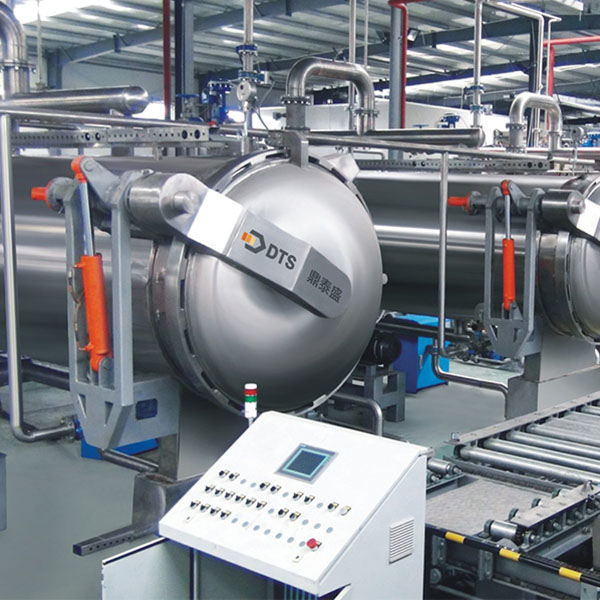

2020 High quality Air Steam Batch Retort Canner Machine - Automated Batch Retort System – Dingtaisheng

2020 High quality Air Steam Batch Retort Canner Machine - Automated Batch Retort System – Dingtaisheng Detail:

Description

The trend in food processing is to move away from small retort vessels to larger shells to improve efficiency and product safety. Larger vessels imply larger baskets that can’t be handled manually. Large baskets are simply too bulky and too heavy for one person to move around.

The need to handle these enormous baskets opens the way for ABRS. ‘Automated Batch Retort System’ (ABRS) refers to the fully automated integration of all hardware designed for transportation of baskets from loader station to sterilization retorts and from there on to an unload station and pack- aging area. The global handling system can be monitored by a basket/pallet tracking system.

DTS can offer you a complete turn-key solution for the implementation of an automated batch retort system: batch retorts, loader/unloader, basket/pallet transport system, tracking system with central host monitoring.

Loader/Unloader

Our basket loading/unloading technology can be used for rigid containers( metal can, glass jar, glass bottles). Besides, we offer tray loading/unloading and tray stacking/destacking for semi-rigid and flexible containers.

Full automatic loader unloader

Semi auto loader unloader

Basket transport system

Different alternatives are available to transport full/empty baskets to/from the retorts, We can provide customized services according to customers’ products and venues. Please consult our expert team for details.

Shuttle car

Automatic basket transport conveyor

System Software

Retort Monitoring Host (Option)

1. Developed by food scientists and process authorities

2. FDA/USDA approved and accepted

3. Use table or general method for deviation correction

4. Multiple level safety system

Retort Room Management

DTS retort monitoring control system is the result of full cooperation between our control system experts and thermal processing specialists. The functional intuitive control system meets or exceeds the requirements of 21 CFR Part 11.

Monitoring function:

1. Multi-level security system

2. Senior recipe edit

3. Table lookup method and mathematical method to calculate F0

4. Detailed process batch report

5. Key process parameter trend report

6. System alarm report

7. Display transaction report operated by operator

8. SQL Server database

Basket tracking system (Option)

The DTS basket tracking system assigns personalities to each basket in the system. This allows operators and managers to immediately view the status of the retort room. The system tracks the whereabouts of each basket and does not allow unsterilized products to be unloaded. In case of abnormal conditions (such as baskets with different products or unsterilized products at unloader), QC personnel are required to review and confirm whether to release marked products.

Screen visualization provides a good system overview of all the baskets, so that only a small number of operators can keep an eye on multiple retort systems.

DTS basket tracking system enables you to:

> strictly distinguishes between sterilized and unsterilized products

> specifies the personality for each basket

> tracks all the baskets in the system in real time

> tracks the hoops’ dwell time deviation

> is not allowed to unload unsterilized products

> tracks the number of containers and production code

> tracks the basket state (i.e., unprocessed, empty, etc.)

> tracks retort number and batch number

System efficiency and maintenance (Option)

DTS system efficiency software helps you keep your retort room running efficiently by tracking production speed, downtime, source of downtime, key submodule performance, and overall equipment efficiency.

> tracks productivity through a customer-defined time window and each module (i.e. loader, trolley, transport system, retort, unloader)

> key sub-module performance tracking (i.e., basket replacement on loader)

> tracks downtime and identifies the source of downtime

> efficiency metrics can be moved to large factory monitors and can be used for cloud-based remote monitoring

> The OEE metric that records on the host is used for record saving or table conversion

Maintainer

Maintainer is a software module that can be added to a machine HMI or run separately on an office PC.

Maintenance personnel track the wear time of key machine parts and inform operators of planned maintenance tasks. It also allows machine operators to access machine documentation and maintenance technical instructions through operator HMI.

The end result is a program that helps plant personnel track maintenance and repair machines effectively.

Maintainer function:

> alerts plant personnel to expired maintenance tasks.

> allows people to see the part number of a service item.

> displays a 3D view of the machine components in need of repair.

> shows all technical instructions related to these parts.

> displays the service history on the part.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for 2020 High quality Air Steam Batch Retort Canner Machine - Automated Batch Retort System – Dingtaisheng, The product will supply to all over the world, such as: Paraguay, America, Brazil, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!