As global demand for canned coconut milk soars, an advanced sterilization retort system has emerged as a transformative force in food safety and production efficiency. This cutting-edge technology, tailored specifically for canned coconut milk, combines precise engineering with automated processes to maintain product integrity and extend shelf life.

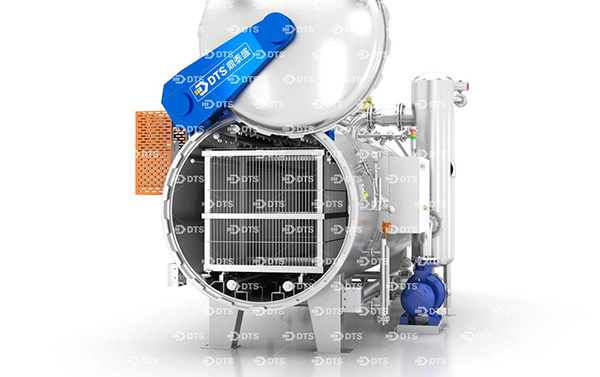

The retort’s operation is centered on a rigorous three-step safety protocol. Initially, baskets filled with canned coconut milk are loaded into the retort chamber, followed by the closure of the door. A triple safety interlock mechanism then engages, mechanically securing the door throughout the sterilization cycle to prevent steam leakage and protect operators. The entire process is autonomously managed by a Programmable Logic Controller (PLC), which executes pre-set sterilization recipes with millisecond precision.

At the onset of the sterilization process, steam is injected through strategically located spreader pipes, rapidly displacing air via vent valves. The come-up phase begins only when both temperature and time parameters are satisfied, ensuring a consistent thermal environment. Throughout the come-up and sterilization phases, the chamber is filled with saturated steam, eliminating any residual air that could lead to uneven heat distribution. Open bleeders enable continuous steam convection, maintaining a temperature variation of less than ±0.5°C across all cans.

This retort system features several revolutionary aspects. Its direct steam heating mechanism allows for rapid temperature increases—reaching 121°C within 5 to 10 minutes—while minimizing heat loss to under 5%. Optional energy recovery modules recycle steam and condensate heat, cutting operational costs by up to 30%. The indirect cooling process, enabled by a heat exchanger, prevents contamination by separating process water from steam and coolant, ensuring compliance with rigorous hygiene standards such as HACCP.

The retort’s versatility extends beyond coconut milk,It caters to a broad spectrum of canned products, from vegetable protein beverages to pet food, by accurately calibrating time-temperature profiles for various container sizes and product densities.

Industry adoption of this technology has already led to significant outcomes. A leading Southeast Asian coconut milk manufacturer reported a 40% decrease in product recalls after integrating the retort system, crediting the improvement to its capability to eliminate heat-resistant pathogens such as Clostridium botulinum.

With the global market for canned goods exceeding $100 billion annually, the sterilization retort is at the vanguard of innovation, offering safer products, diminished environmental impact, and increased consumer confidence. As ongoing research aims to incorporate artificial intelligence for real-time process optimization, the future of canned food production appears both secure and sustainable.

Post time: May-21-2025