High-temperature sterilization allows food to be stored at room temperature for months or even years without the use of chemical preservatives. However, if sterilization is not carried out in accordance with standard hygienic procedures and under a suitable sterilization process, it may pose food safety problems.

Some microbial spores can withstand high temperatures and produce toxins that are hazardous to human health. This is the case with botulism, a serious illness caused by botulinum toxin produced by the bacterium Clostridium botulinum.

Botulism poisoning usually has very serious consequences.2021 A family purchased vacuum-packed ham sausage, chicken feet, small fish, and other snacks at a small store and consumed them at dinner, and the next day a family of four all suffered from vomiting, diarrhea, and weakness of the limbs, resulting in the serious consequences of one death and three people under observation in the intensive care unit. So why is there still foodborne botulinum toxin poisoning in vacuum-packed foods?

Clostridium botulinum is an anaerobic bacterium, which is generally more common in meat products, canned food and vacuum-packed food. Usually people will use high temperature sterilization method to sterilize the food, the product in the sterilization, in order to ensure that the sterilization is thorough must be sterilized in the retort for a long enough time to kill the harmful bacteria and their spores in the food.

To avoid botulism, there are a few things to take extra care of:

1.Use fresh raw materials that meet sanitary standards for preparation.

2.Thoroughly clean all used utensils and containers.

3.Ensure that product packaging is sealed tightly.

4.Follow reasonable sterilization temperatures and durations.

5.Sterilization treatment parameters depend on the type of food to be preserved.

For acidic foods (pH less than 4.5), such as fruits, they are naturally more resistant to botulism. Sterilization by boiling water (100°C) for a time adapted to the packaging format and the product concerned is sufficient.

For low-acid foods (pH greater than 4.5), such as meat, fish, and cooked vegetables, it must be sterilized at a higher temperature to kill Clostridium botulinum spores. Sterilization under pressure with a temperature above 100°C is recommended. The required process will depend on the product and its format, with average temperatures being around 120°C.

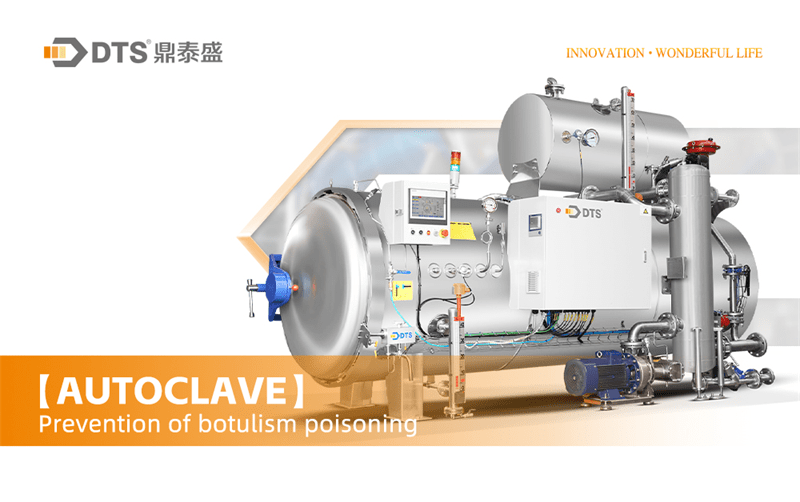

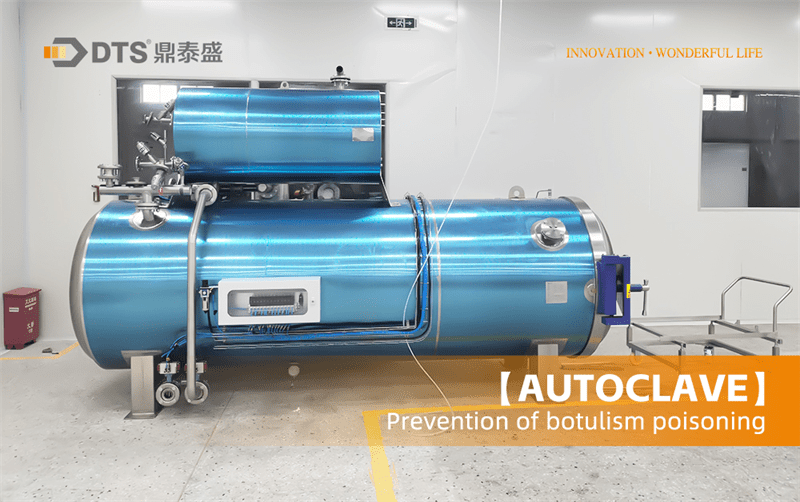

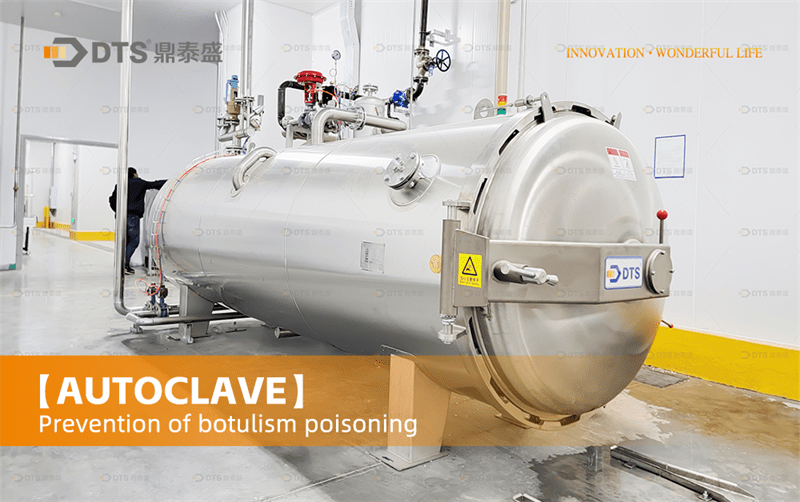

Clostridium botulinum: sterilization by industrial autoclave

Industrial autoclave sterilization is the most effective sterilization method for killing Clostridium botulinum, the bacterium that causes botulism. Industrial autoclaves can reach much higher temperatures than domestic autoclaves, ensuring the destruction of pathogens.

DTS autoclave retort ensures good temperature distribution and cycle repeatability in the vessel, which is a safety guarantee for safe sterilization.

DTS retort: Sterilization with confidence

DTS offers a wide range of autoclaves for the food industry. The design of these retorts ensures excellent uniformity of heat distribution during the food sterilization process, guaranteeing a homogeneous sterilizing effect for all products loaded. The control system of the autoclave ensures the safety of the food process and guarantees perfect cycle repeatability.

In addition, our team of experts will provide you with technical support on the use of autoclaves for safe and reliable product sterilization.

Post time: Feb-01-2024